Dynamics Group

Fundamental Technology Research Center

Research & Development Center

Innovation & Technology Division

YANMAR Technical Review

Development of Agricultural Spraying Method with Reduced Spray Use and Improved Leaf Coverage

Innovative New Technique for Tractor-Mounted Sprayers

Abstract

In pesticide spraying, the extent of spray drift to areas other than target crops is proportional to the amount sprayed. Along with the high price of pesticides, this makes reducing the amount sprayed desirable both for the environment and for agricultural management. The problem with conventional methods, unfortunately, is that reducing the amount sprayed degrades spraying performance. This article describes the research and development of a tractor-mounted sprayer that combines two-stage spraying with a leaf-turning mechanism. By doing so, the sprayer both reduces the quantity of spray used and improves the coverage, achieving similar performance to existing methods while using only 60% as much spray. The newly developed system has been incorporated into the new WS300 pesticide sprayer for vineyards launched by Yanmar Agribusiness in May 2023.

WS300 movie link: https://youtu.be/3wmBkgOHu2U

1. Introduction

The spraying of agricultural chemicals plays an important part in maintaining produce yield and quality and in reducing cultivation workloads. In a manual on dealing with the problem of spray drift (pesticides or other agricultural chemicals that drift away from the target crop), Japan’s Ministry of Agriculture, Forestry and Fisheries has identified it as a national issue, noting also that the amount of drift is proportional to the amount sprayed(1). The high price of agricultural chemicals is also an issue(2), driven by rising prices for raw materials, transportation, and other inputs. This makes reducing the volume of sprayed pesticides desirable both for the environment and for agricultural management.

The requirement for an agricultural sprayer is to achieve a uniform distribution across the target crop while using the bare minimum of spray. There is a particular emphasis on getting sufficient pesticide to the sheltered undersides of leaves that more easily retain moisture and provide a fertile site for pathogens. The problem with existing practices such as the use of speed sprayers like that shown in Fig. 1 (hereinafter, “conventional spraying”) is that they spray pesticide in a single direction despite the different orientations of the top and undersides of the leaves. In particular, the way they spray onto the top sides of leaves is not a good way to reach the lower branches of trees or the inward facing underside of leaves, meaning that adequate coverage cannot be ensured if the amount of spray used is reduced.

This article describes the research and development of a sprayer equipped with new mechanisms that address this problem.

2. Development of New Concept

As the upper and lower sides of a leaf face in opposite directions, it is difficult for ordinary spraying to get pesticide to both sides at the same time. Accordingly, the initial solution was to adopt two-stage spraying, using two separate sprayers set up to target the upper and lower sides respectively. The second solution was to incorporate a mechanism that would forcibly turn the undersides of leaves toward the spray nozzle. Reorienting leaves requires some sort of external force, whether it be blown air, electricity, magnetism, gravity, buoyancy, or physical contact. Considering factors such as the practicality of fitting such a mechanism on an agricultural sprayer and the potential for damage to the plant, the decision was made to use blown air for this purpose. The technique has been named “air assist” and its use for leaf-turning has proven to be an effective way to get spray to the undersides of leaves. These two solutions are used in tandem to address the issues highlighted in the introduction above, thereby creating a new concept that combines two-stage spraying with a leaf-turning mechanism.

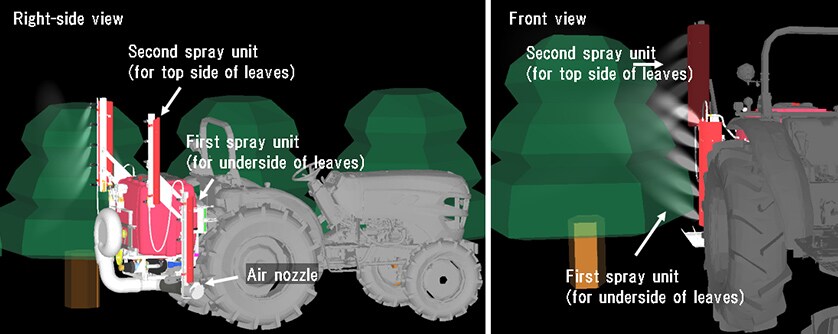

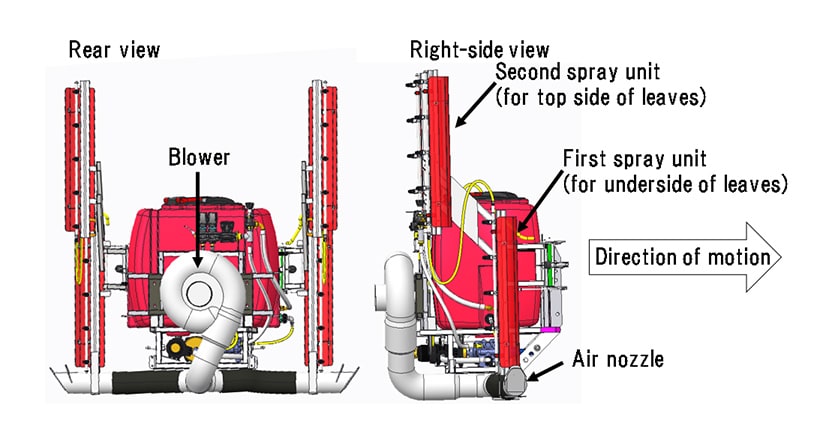

Fig. 2 shows the new spraying concept and Fig. 3 shows the mechanism. The system is equipped with two spray units that spray from above and below to reach the upper and lower sides respectively of the leaves. The first spray unit is located near the rear of the tractor and works by spraying upwards onto the undersides of the leaves as they are exposed by the air blown upwards from the air assist nozzle. The second spray unit is located far enough to the rear of the first unit to be outside the range of the air assist, allowing it to spray downwards onto the top of the leaves after they have returned to their original orientation.

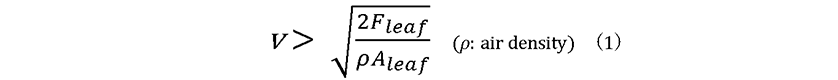

The air velocity  required to turn a leaf is calculated using equation (1) based on the required force,

required to turn a leaf is calculated using equation (1) based on the required force,  , and the leaf area,

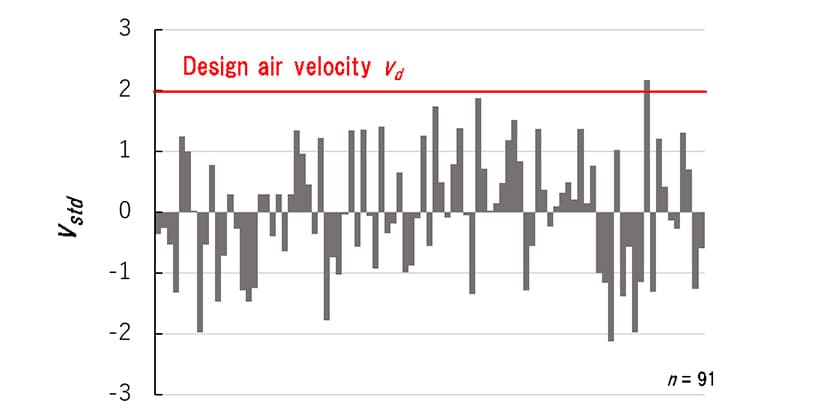

, and the leaf area,  , measured for the field where the sprayer is to be used. Fig. 4 shows the value of

, measured for the field where the sprayer is to be used. Fig. 4 shows the value of  , the standardized air velocity required to turn a leaf. To allow for the variability that exists in plants, the design air velocity

, the standardized air velocity required to turn a leaf. To allow for the variability that exists in plants, the design air velocity  (the minimum required air velocity to turn the leaves) was set based on twice the standard deviation, as shown in the graph. This both improves the coverage of pesticide on the leaves and minimizes the amount of drift to the surrounding environment.

(the minimum required air velocity to turn the leaves) was set based on twice the standard deviation, as shown in the graph. This both improves the coverage of pesticide on the leaves and minimizes the amount of drift to the surrounding environment.

Fig. 4 Standardized Air Velocity Required to Turn a Leaf ( ) and Design Velocity (

) and Design Velocity ( )

)

3. Testing of New Concept

3-1. Use of CFD to Evaluate Efficacy of New Concept

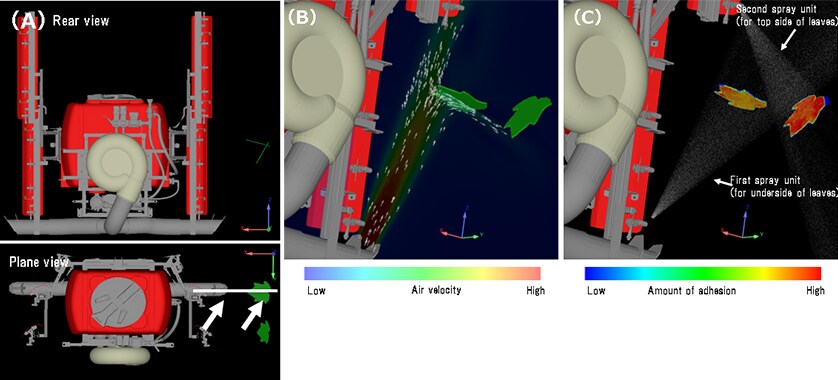

Computational fluid dynamics (CFD) was used to predict how well the new concept would work by determining the air velocity in the vicinity of a leaf, the behavior of the spray droplets, and the amount of spray that reaches the leaf surface. Fig. 5 (B) shows a contour map of velocity and velocity vectors for the air blown by the air assist mechanism, as seen from the white arrows in Fig. 5 (A). In the contour map of velocity, red indicates regions of higher air speed and blue indicates lower speed. This shows that the air velocity at the lower part of the leaf in line with the air nozzle direction exceeds the design velocity ( ). Fig. 5 (C) shows droplet behavior and the amount of pesticide coverage on the leaf surface, viewed from the same direction as in Fig. 5 (B). Here, red indicates regions of high pesticide coverage and blue indicates lower coverage. The results show that a sufficient pesticide coverage on the underside of the leaf by the first spray unit and to the top side by the second spray unit.

). Fig. 5 (C) shows droplet behavior and the amount of pesticide coverage on the leaf surface, viewed from the same direction as in Fig. 5 (B). Here, red indicates regions of high pesticide coverage and blue indicates lower coverage. The results show that a sufficient pesticide coverage on the underside of the leaf by the first spray unit and to the top side by the second spray unit.

3-2. Spray Performance Evaluation Method

The spray performance is evaluated in terms of how many droplets adhere to the upper or lower sides of the leaf (coverage). As shown in Fig. 6 (A), coverage is assessed by positioning moisture-sensitive paper (paper that changes color on contact with droplets) on the upper or lower sides of random leaves and then using image processing to calculate the percentage of leaf surface area covered by spraying(3). The water-sensitive paper turns purple where it comes into contact with a spray droplet and remains yellow elsewhere. Fig. 6 (B) shows examples of the water-sensitive paper after receiving different levels of coverage.

3-3. Spray Performance in Field Testing

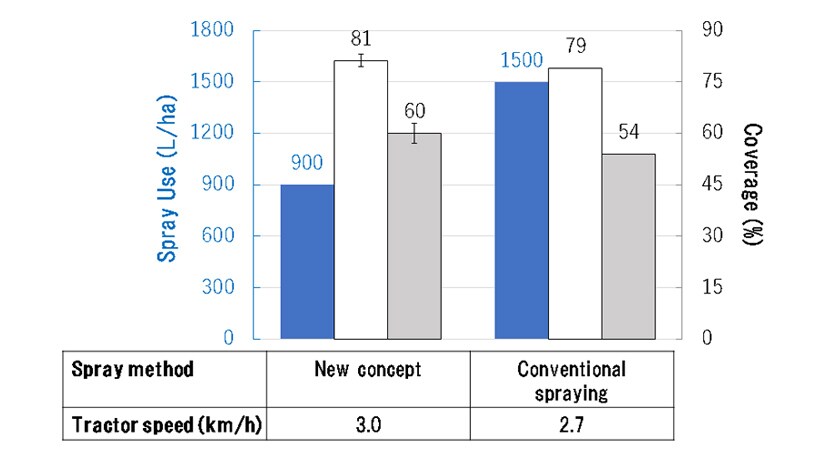

The prototype shown in Fig. 7 was built to evaluate how well the new spraying concept performs. Field trials were conducted to compare its performance to that of conventional spraying with a speed sprayer. Fig. 8 shows the field test conditions and results. Although the new concept only used 60% as much spray as the conventional sprayer (900L/ha vs. 1,500L/ha), it achieved a 6% improvement in underside leaf coverage (60% vs. 54%). This is believed to be due to the benefits of the leaves being turned over by the air assist mechanism and the upward spraying action of the first spray unit. Coverage of the top sides of leaves was also slightly better than that achieved by conventional spraying (81% vs. 79%). This indicates that the downward orientation of the second spray unit successfully reaches the top sides of leaves. As similar coverage was achieved despite using only 60% as much spray as conventional spraying, this should equate to a proportionate 40% reduction in spray drift, as explained in the introduction, demonstrating that the new concept will have less of an impact on the surrounding environment than conventional spraying.

4. Conclusions

This article has described the research and development of a tractor-mounted sprayer that can deliver a similar quantity of spray to foliage while using less spray than conventional spraying. The new sprayer design combines two-stage spraying with an air assist mechanism for leaf-turning to reduce spray usage while improving leaf coverage. It has been fitted to the new Yanmar WS300 vineyard sprayer (for crops grown on trellises) that went on sale from Yanmar Agribusiness in May 2023(4). Along with the supply of safe, trouble-free, and low-cost viticulture solutions that include other agricultural machinery such as mowers or the T100S-V(A) pruning system(5), Yanmar also plans to extend the use of the new spraying concept beyond vineyards to other growing systems. By doing so, it intends to play its part in addressing the needs of customers and wider society by providing agricultural practices that are both cost-effective and gentle on the environment.

WS300 video: https://youtu.be/3wmBkgOHu2U

References

- (1)Ministry of Agriculture, Forestry and Fisheries, Manual of Measures for Preventing Spray Drift, March 2010 in Japanese.

- (2)Bank of Japan, Agricultural Corporate Goods Price Index, August 2023 in Japanese

- (3)Yosuke Kubota, Development of Image-Processing Software for Simple and High-Precision Measurement of Cover-Area Ratio on Water-Sensitive Paper, Agricultural Information Research, 19, 2, pp.16-22, 2010 in Japanese

- (4)WS300 electrostatic boom sprayer for vineyards (for crops grown on trellises)

https://www.yanmar.com/jp/agri/products/implements/ws300/ - (5)T100S-V(A) pruning system

https://www.yanmar.com/jp/agri/products/implements/t100s-v/

Related Patents

Patent 7283007, Agricultural Sprayer, Kazuaki Hirasawa (Yanmar Holdings Co., Ltd.), Soichiro Ikegami (Yanmar Holdings Co., Ltd.), Hirofumi Ukai (Yanmar Holdings Co., Ltd.), Yoshihiro Yoshida (Arimitsu Industry Co., Ltd.)

WO2021193845 Chemical Agent-Spraying Device, Kazuaki Hirasawa (Yanmar Holdings Co., Ltd.), Soichiro Ikegami (Yanmar Holdings Co., Ltd.), Hirofumi Ukai (Yanmar Holdings Co., Ltd.), Yoshihiro Yoshida (Arimitsu Industry Co., Ltd.)

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Innovation & Technology Division, Technology Strategy Division.

Author

Agriculture

Agriculture

Recreational Marine

Recreational Marine

Recreational Boat

Recreational Boat

Premium Cruiser

Premium Cruiser

Marine Equipment

Marine Equipment

Marine Commercial

Marine Commercial

Propulsion Engines (High Speed)

Propulsion Engines (High Speed)

Propulsion Engines (Medium Speed)

Propulsion Engines (Medium Speed)

Auxiliary Engines

Auxiliary Engines

SCR System

SCR System

Dual Fuel Engine

Dual Fuel Engine

Two-stage Turbocharging System

Two-stage Turbocharging System

Electric Propulsion System

Electric Propulsion System

Energy Systems

Energy Systems

Compact Equipment

Compact Equipment

Industrial Engine

Industrial Engine

Power Generation

Power Generation

Compact Power Products

Compact Power Products