Composter Group, Prototype Development Department

Innovation Center, Technology Division

Yanmar Holdings Co., Ltd.

YANMAR Technical Review

YC100 Composter*1 for Resource Recycling Food Production

Abstract

Yanmar’s YC100 composter was developed to facilitate recycling in food production. Its features include stirring claws, the Air Direct Injection system, and weight measurement for use in operational control. Turning food waste into compost and supplying it to farms also helps to reduce dependence on chemical fertilizers.

This article gives examples of some of the possibilities for using the composter. In one, at a nursery school, it is helping to educate children about food and the environment. Another example from Hamada City in Shimane Prefecture takes advantage of the unique characteristics of the region to recycle marine waste for use on farms.

The YC100 has the potential to assist not only with solving the problem of waste disposal, but also with achieving the SDGs, including by reducing environmental impacts. Yanmar is also seeking to build a sustainable and future-oriented society through a model for regional revitalization that features the resource recycling and encompasses the different places on land, sea, or city where Yanmar conducts its business.

- *1A device for turning organic waste into compost.

1. Introduction

1-1. SDGs and “A Sustainable Future”

Inspired by its brand statement of “A Sustainable Future,” the Yanmar Group has set out to develop resource-recycling food production systems. In doing so, it is addressing Sustainable Development Goals (SDGs) 2 (zero hunger), 12 (responsible consumption and production), 13 (climate action), and 15 (life on land).

1-2. Dealing with Food Waste

The production, processing, and consumption of foods such as vegetables, seafood, or meat generates various forms of waste, including inedible material and food past its expiry date. Globally, this amounts to 930 million tons representing 17% of total food production (2019, UNEP). In Japan, 23.72 million tons of food goes to waste each year (2020, Ministry of Agriculture, Forestry and Fisheries of Japan).

1-3. How Composters Can Address Societal Issues

While not letting food go to waste in the first place is clearly important, feeding the food waste that does require disposal into a composter allows it to be reused to grow more food. If recycling food like this can cut the use of chemical fertilizer, a resource that is largely imported and that has increased significantly in price over recent years, it should also help to reduce costs for growers.

This article describes the YC100 composter. Already commercially available, the YC100 was designed to process 100 kg of organic waste a day at supermarkets or food processing companies. While this is an application where waste is generally easier to collect, being concentrated in one place, its recycling is complicated by the variability of composition and the fact that waste volumes tend to change from day to day. Since then, however, the YC100 has found a variety of applications and new uses that were never envisaged when it first went on the market. Section 3 below provides some examples.

2. Composter Characteristics and How it Works

Composters can be broadly divided into those that use wet and dry composting. For the purpose of recycling food waste, Yanmar developed a dry bio-composter.

2-1. Wet Composting Discharges most Treated Material in Waste Fluid

Wet composters work by supplying water and stirring the material being composted. The resulting fluid is then discharged from the mixing tank. Accordingly, these composters are good at reducing the quantity and volume of material and require less frequent emptying of treated residue. However, most of the nutritional content of the food waste is carried off in the discharged fluid. Table 1 lists the changes in electrical conductivity (EC) of different compost materials after exposure to water to simulate wet composting. EC is an indicator of the quantity of nutrients present in soil or compost materials. These results indicate that one stirring cycle washes away about 30 to 40% of the nutrients in the composted materials. As discharging this fluid into waterways has the potential to cause eutrophication or algal blooms, septic tanks or some other form of post-treatment is required. Moreover, reducing the quantity of compost and its nutrient content defeats the purpose of recycling.

2-2. Dry Composting Extracts Treated Material

YC100 is a dry bio-composter that works by first placing a bacterial feedstock in the composting chamber and then adding the food waste. The stirring claws are then used to mix this material while heated air is injected to promote drying. Also, raising the temperature of the composting material promotes decomposition by providing an environment conducive to bacterial mobility. Because the composting process does not require any water or produce any fluids, there is no leaching of the nutrients contained in the food waste. Similarly, no waste water treatment is required. This lack of drainage of any liquid waste minimizes the impact on the surrounding environment and results in compost that retains more of its nutrients than is the case with wet composting.

Table 1 Changes in Compost EC Before and After Rinsing to Simulate Wet Composting

| Material | Electrical conductivity: EC (mS/cm) | Leaching (%) | |

|---|---|---|---|

| Before rinsing | After rinsing | ||

| Bark compost | 0.57 | 0.42 | 26 |

| Poultry manure | 6.1 | 4.0 | 34 |

| Cow manure | 4.7 | 2.9 | 38 |

An electrical conductivity meter (HORIBA, Ltd., LAQUAtwin, EC-33B) was used to measure the EC of three different types of commercial compost in their original state and after they had been mixed with three times their volume of water, stirred, and then recovered using a filter. The EC is indicative of the quantity of nutrients present.

2-3. YC100 Features

2-3-1. Claw-shape Design for High Stirring Efficiency

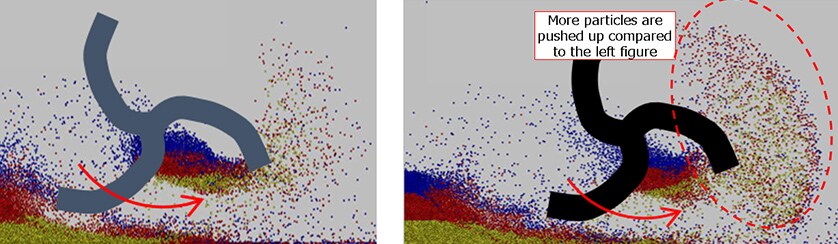

The YC100 can break up food waste quickly due to the highly efficient stirring action provided by the shape of its claw. This design draws on rotary expertise that Yanmar has built up over many years in its work on tractors. Moreover, as shown Fig. 1, the shape of the claw is such that a lot of particles end up in the rear area above it (the region enclosed by the red dotted line in the righthand figure). This is because the claw shape stirs up a lot of material from the surface of the compost at the bottom of the chamber. By doing so, it not only shortens the drying time, but also suppresses anaerobic fermentation and its accompanying strong odors by reducing the amount of material that has limited exposure to air.

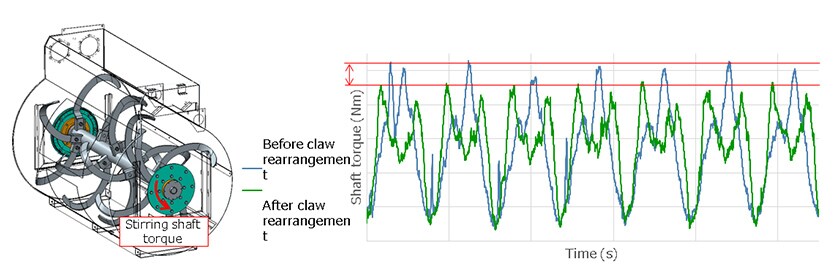

The stirring claws have also been positioned in a particular way that prevents material from piling up in specific parts of the chamber and enables a steady torque to be maintained. As a result, the peak stirring shaft torque has been reduced by about 20% (see Fig. 2). As a lower peak torque means steadier mechanical operation, this extends the machine life.

2.3.2 Air Direct Injection (ADI) into Composter Chamber

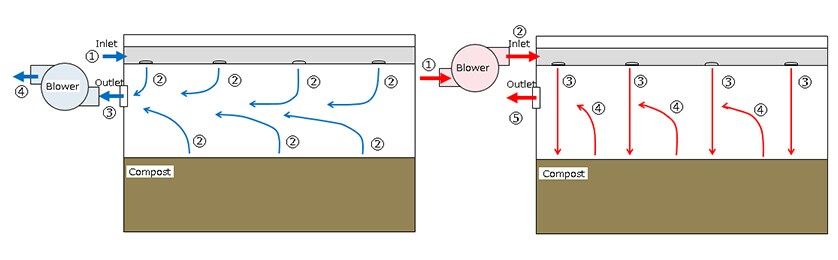

Passing heated air through the stirring chamber is necessary to speed up drying of the material inside. Fig. 3 shows diagrams of the airflow in the chamber for different injection methods. Standard practice in the past was to draw air into the chamber, as shown by the diagram on the left in Fig. 3. The problem with doing it this way, however, is that the drying efficiency is degraded because heated air from near the inlets is expelled before it has time to come into contact with the compost. In contrast, the YC100 increases the amount of air that contacts the compost by forcing air into the stirring chamber from above, as shown on the right in Fig. 3. This results in more efficient drying. It also helps to prevent anaerobic fermentation.

2.3.3 Weighing for Operational Control and Safety Mechanisms

As the amount of food waste often varies from day to day, some way is needed to control the composter in accordance with the changing amounts of incoming material. Especially when the amount of incoming waste is low, it is important to reduce the output to reduce both the economic and the environmental costs. As the YC100 is equipped with load cells in each of its four feet (see Fig. 4), it can weigh how much material is put into it and control its operation accordingly. The machine is also designed for safe operation and a long life. By displaying the measured weight, it can help users avoid exceeding the amount of new material that can be added to the composter each day and also notify them when material needs to be removed.

3. Example Applications

The YC100 has been well received since it first went on sale in December 2021, having been supplied to users such as food processing companies, supermarkets, shopping malls, and local government agencies. This section describes example applications at Umenohana, a Japanese restaurant chain, and at a nursery school.

3-1. Installation at Umenohana

Umenohana is a Japanese restaurant chain that has made the SDGs part of its management strategy and wants to play its part in solving societal challenges. It operates around 288 sites across Japan, including Chinese restaurants, restaurants that specialize in crab dishes, and dedicated takeout operations. The company’s Kyoto and Kurume central kitchens that supply these sites generate approximately 270 t of food waste annually, with annual disposal costs of around 14 million yen. It was to address these issues that they chose to install YC100 composters (see Fig. 5).

By installing the composters, Umenohana was able to establish the circular recycling system shown in Fig. 6 below. Food waste from the central kitchens is composted in the YC100s to produce an intermediate product that is then collected and mixed with cow dung to produce a complete mineral-rich compost. The compost goes to growers who use it on crops that are in turn used in Umenohana’s central kitchens for supply to its retail outlets. The results have included an approximate 80% reduction in disposal costs and less use of expensive chemical fertilizer. In the future, Umenohana plans to progressively expand this food waste recycling to more of its processing centers and restaurants.

3-2. Installation at Nursery School

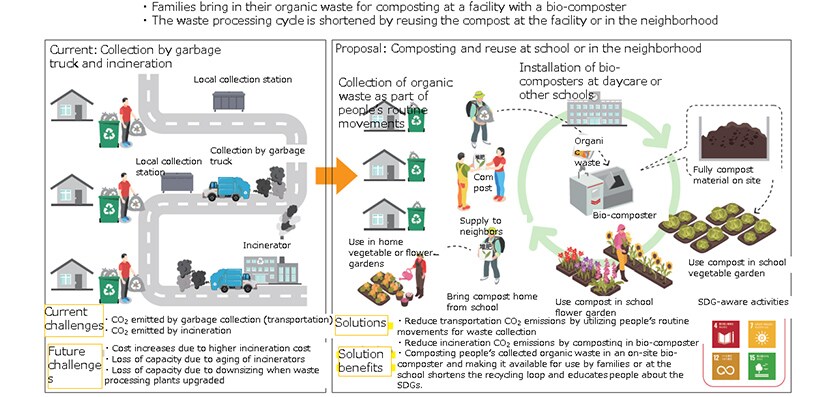

Local governments have been stepping up action not only to reduce the costs of waste disposal, but also to protect the environment and help realize a circular economy. The Otakinomiya Kindergarten operated by Taga, a town in Shiga Prefecture, has installed a YC100 composter and is running trials in collaboration with the Taga municipality. As shown in Fig. 7, the trial has the children and their guardians bring organic waste from home with them to the nursery school. The waste is put into the YC100 at the school and turned into high-quality compost for use in the school’s own vegetable garden. It is also available for use by local residents in the growing of flowers or vegetables.

Any emission of CO2 in the collection process is minimized by taking advantage of the trip to the nursery school, which people would be making anyway. The trial succeeded in collecting organic waste from about 80% of its families. They also developed a biodegradable bag for holding the waste, avoiding the need to empty the waste out of the bag when feeding it into the YC100. The project is still ongoing and at the time of writing had already collected a total of 4 tons of organic waste. The plan is to further expand the scope of recycling beyond the nursery school by utilizing other situations where people travel to local government facilities.

4. Conclusions

4-1. Food Production with Recycling and Low Environmental Impact

The YC100 composter was developed and marketed to help reduce the use of chemical fertilizer in food production by enabling resource recycling whereby unavoidable food waste is recycled and supplied to farms where it is used to grow crops. This objective is being realized through work being done with companies such as Umenohana in the food processing industry, the product’s initial target market.

4-2. Future-Oriented Society with Resource Recycling in Cities, on Farms, and at Sea

As with the nursery school in Taga, recycling initiatives are spreading to applications and organizations that were not initially envisaged for the composter. When guardians of children attending the nursery school were surveyed, the responses included comments that it was helping children be more mindful of sorting trash while also raising environmental awareness among adults. Use of the composter for recycling is also fostering belief in the idea of local government and the community working together to resolve challenges that face society as a whole.

The composter is also finding uses in distinctive and attractive forms of regional revitalization, such as raising environmental awareness in the community and the on-farm use of fisheries waste that in turn benefits the richness of the oceans.

As well as using the YC100 composter as a means of overcoming the challenges of waste processing, Yanmar also wants it to play a role in achieving the SDGs, including reducing the load on the environment. Yanmar is also seeking to promote a variety of new uses for the composter, whether it be in regional revitalization models that feature the recycling of resources and encompass the different places on land, sea, and city where Yanmar conducts its business, or working to build a sustainable and future-oriented society with the help of communities and the children who represent the future.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Innovation & Technology Division, Technology Strategy Division.

Author

Bio Innovation Center

Central Research Institute, Technology Division

Yanmar Holdings Co., Ltd.

Atsumi Konishi

Yanmar E-Stir Co., Ltd.

Agriculture

Agriculture

Recreational Marine

Recreational Marine

Recreational Boat

Recreational Boat

Premium Cruiser

Premium Cruiser

Marine Equipment

Marine Equipment

Marine Commercial

Marine Commercial

Propulsion Engines (High Speed)

Propulsion Engines (High Speed)

Propulsion Engines (Medium Speed)

Propulsion Engines (Medium Speed)

Auxiliary Engines

Auxiliary Engines

SCR System

SCR System

Dual Fuel Engine

Dual Fuel Engine

Two-stage Turbocharging System

Two-stage Turbocharging System

Electric Propulsion System

Electric Propulsion System

Energy Systems

Energy Systems

Compact Equipment

Compact Equipment

Industrial Engine

Industrial Engine

Power Generation

Power Generation

Compact Power Products

Compact Power Products